FAQ

What does Defect classification mean? |

||||||||||||

|

Defect classification:

|

||||||||||||

What does Sampling standard mean? |

||||||||||||

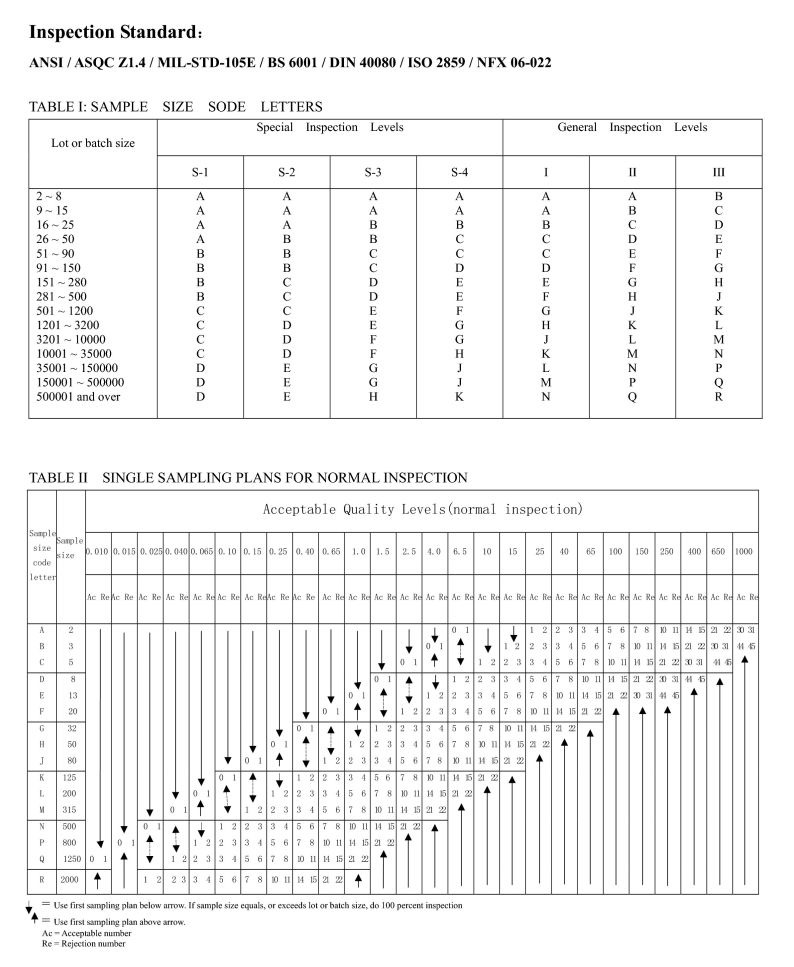

| Sampling standard: The size of samples used during the inspections is determined on the basis of HQTS uses the MIL STD 105E tables, which are recognized standard in all branches of industry. This American standard has now equivalents in all national and international standardization organizations. Basically, this standard is a proven method of accepting or rejecting a production lot by inspecting a randomly selected lot of product.  |

||||||||||||

What does AQL mean? |

||||||||||||

| Acceptable Quality Level (AQL): It means the value of defects, expressed as a percentage by the particular sampling procedure and the level used will identify what the buyer will normally accept in the majority of cases. Different AQLs may be established for different defect classifications such as Critical, Major and Minor.

|

Auditing

Auditing Testing

Testing Consulting

Consulting Inspection

Inspection Industry

Industry